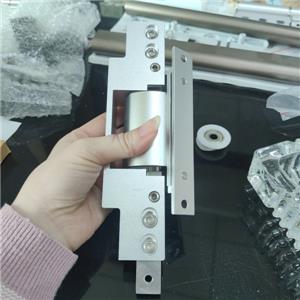

Handling the Anodizing of Aluminum Door and Window Hinges

Anodizing is a crucial process for enhancing the durability and corrosion resistance of aluminum door and window hinges. Proper handling during anodizing ensures quality and extends hinge life, making them suitable for long-term use in various environments.

Preparation

Before anodizing, thoroughly clean the aluminum hinges to remove any grease, oils, or contaminants. A mild alkaline or acid cleaning solution is commonly used. After cleaning, the hinges are rinsed and checked for surface imperfections, as even small defects can affect the anodized finish.

Anodizing Process

During anodizing, the hinges are immersed in an electrolytic solution, typically sulfuric acid. A direct current passes through, creating a protective oxide layer. This layer enhances corrosion resistance and can also be dyed in various colors. For door and window hinges, a clear or natural anodized finish is often preferred to maintain a sleek, metallic look.

Post-Anodizing

After anodizing, the hinges must be properly sealed to lock in the oxide layer. Hot water sealing or chemical sealing processes are common methods. Proper drying and careful handling are crucial to avoid scratches or damage to the newly anodized surface.

In summary, careful handling before, during, and after anodizing is essential to ensure high-quality aluminum door and window hinges that are durable and corrosion-resistant.

WSMT supply premium quality aluminium accessories for windows and doors.

Welcome to contact us: whatsapp/Wechat/Zalo+86 150 156 88141

Email:catherine@weisidunwj.com