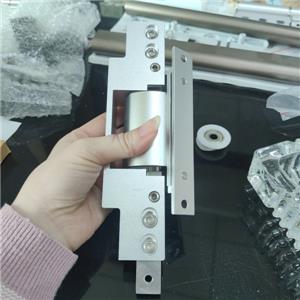

Anodized process of aluminum door and window hinges

The anodizing process for aluminum door and window hinges involves several steps:

Preparing the hinges: Start by thoroughly cleaning the hinges to remove any dirt, grease, or contaminants from the surface. This can be done using a mild detergent and water solution or a degreaser. Rinse the hinges with clean water and dry them completely.

Chemical pretreatment: The hinges are immersed in a chemical solution to prepare the surface for anodizing. This step typically involves etching or desmutting the aluminum surface to remove any oxide layers or impurities. The specific chemicals and processes used for pretreatment can vary depending on the anodizing facility.

Anodizing bath: The pretreated hinges are then immersed in an anodizing bath. This bath contains an electrolyte solution, typically sulfuric acid, which acts as the electrolyte for the anodizing process. The hinges serve as the anode (positive electrode) while a cathode (negative electrode) is also present in the bath.

Anodizing: An electric current is passed through the bath, causing an oxidation reaction to occur on the surface of the hinges. This results in the formation of a durable and protective layer of aluminum oxide. The thickness of this oxide layer can be controlled by adjusting the voltage and the time the hinges spend in the bath. The anodizing process typically takes place at room temperature.

Dyeing (optional): If desired, the anodized hinges can undergo a dyeing process to add color to the surface. This involves immersing the hinges in a dye solution that is absorbed into the porous oxide layer. Various dyes are available to achieve different colors. The hinges are then rinsed and sealed to lock in the dye.

Sealing: After anodizing and dyeing (if applicable), the hinges are rinsed to remove any residual chemicals and then sealed. Sealing is done to close the pores in the anodized layer, enhancing its corrosion resistance and durability. Sealing may involve hot water rinsing, steam sealing, or using a sealant solution.

Quality inspection: Once the hinges have been anodized and sealed, they undergo a quality inspection to ensure that the anodized layer is uniform, free from defects, and meets the required specifications. This may involve visual inspection, measurement of coating thickness, adhesion testing, and other quality control checks.

It's important to note that the specific anodizing process can vary depending on factors such as the desired finish, the anodizing facility, and the specific requirements of the hinges. Working with a professional anodizing service provider is recommended to ensure the best results.

WSMT supply premium quality aluminium accessories for windows and doors.

Welcome to contact us: whatsapp/Wechat/Zalo+86 150 156 88141

Email:catherine@weisidunwj.com