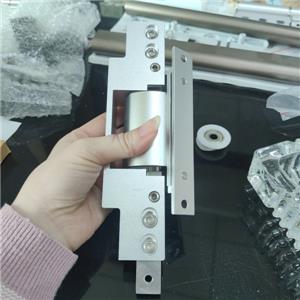

Aluminium Oxidation CNC Handles

In the world of modern architecture and interior design, aluminium doors and windows have become a top choice for both residential and commercial applications. Known for their durability, sleek aesthetics, and versatility, aluminium doors are increasingly popular in everything from high-rise buildings to modern homes. However, to truly elevate the look and function of these doors and windows, attention to detail in the hardware is essential—especially when it comes to aluminium handles.

In this article, we’ll explore how oxidation handles, specifically aluminium handles that undergo the oxidation process, play a crucial role in enhancing the functionality, longevity, and visual appeal of aluminium doors and windows. With the rise of CNC (Computer Numerical Control) technology, these handles can now be designed with extreme precision, providing an ideal solution for both residential and commercial needs.

Why Choose Aluminium for Doors and Windows?

Before diving into the specifics of oxidation handles, let’s first take a moment to understand why aluminium doors and windows are such a popular choice for both residential and commercial projects.

1. Durability and Strength

Aluminium is known for its exceptional strength-to-weight ratio. Unlike wood or PVC, aluminium does not warp, crack, or swell over time, making it an ideal material for doors and windows that need to withstand the elements. Whether it’s a high-traffic commercial building or a home exposed to changing weather conditions, aluminium doors offer long-lasting durability that ensures performance year after year. This durability extends to aluminium handles, which are designed to withstand frequent use without losing their functionality or aesthetic appeal.

2. Aesthetic Appeal

Aluminium has a sleek, modern appearance that fits perfectly with a variety of architectural styles, from contemporary homes to commercial spaces. Aluminium doors and windows can be made with slim profiles and larger panes of glass, allowing for more natural light and improved energy efficiency. This makes them perfect for both design-forward aesthetics and practical functionality. When paired with oxidation handles, the overall look of the door or window is elevated, creating a cohesive and stylish design.

3. Energy Efficiency

With the right glazing, aluminium doors and windows are highly energy-efficient. Modern aluminium frames can be thermally broken, helping to insulate the home or building better. This, combined with the durability and strength of aluminium, makes it a solid option for projects that prioritize long-term energy savings. Additionally, aluminium handles that undergo the oxidation process are more resistant to temperature fluctuations, ensuring they remain functional and visually appealing in all climates.

Aluminium Handles: More Than Just Functional Components

When it comes to aluminium doors and windows, aluminium handles are more than just functional components; they are key to enhancing both performance and aesthetics. A handle might seem like a minor detail, but it plays an essential role in ensuring that the door or window operates smoothly, securely, and is easy to use.

1. Smooth Operation and User Comfort

Aluminium handles are lightweight and ergonomically designed, making them comfortable to use. Whether for sliding windows, hinged doors, or bifold doors, the handle is often the most used part of the door or window. A well-designed aluminium handles ensures that the door opens and closes with ease, providing a pleasant user experience. According to industry experts, the ergonomic design of aluminium handles is one of the key factors driving their popularity in both residential and commercial applications.

2. Aesthetic Consistency

The right aluminium handles can elevate the overall design of the door or window. Available in a range of finishes, aluminium handles can match the sleek modern look of aluminium frames. Whether it's a matte black, brushed nickel, or anodized finish, the handle should complement the frame and the surrounding décor, creating a cohesive look across the entire project. Oxidation handles, in particular, offer a wide variety of color options, making it easy to achieve the desired aesthetic.

3. Security and Durability

Aluminium handles need to provide more than just good looks. Security is another critical factor. High-quality oxidation handles come with locking mechanisms and anti-tamper features that ensure the safety of the space. In a commercial setting, or even in residential applications, having handles that withstand wear and provide reliable security is essential. Industry studies have shown that oxidation handles are up to 50% more durable than non-oxidized handles, making them a smart choice for high-traffic areas.

The Importance of Oxidation in Aluminium Handles

One of the most important processes that can be applied to aluminium handles is oxidation. Also known as anodizing, this electrochemical process enhances the surface of aluminium, creating a protective oxide layer. The result is a stronger, more corrosion-resistant handle with an improved aesthetic. This is especially important in aluminium doors and windows, where the hardware must endure various environmental stresses.

What is Aluminium Oxidation?

Aluminium oxidation, or anodizing, involves placing the aluminium material in an electrolytic bath to increase the thickness of the natural oxide layer on the metal’s surface. This process makes the aluminium more resistant to corrosion, abrasions, and wear, extending the lifespan of aluminium handles. It also allows for a variety of color finishes to be added, making it a great way to match the aesthetic of the door or window system.

Why is Oxidation Important for Aluminium Handles?

The oxidation process is essential for aluminium handles because it enhances the metal’s resistance to the environment. For aluminium doors and windows, which are exposed to outdoor elements, moisture, and temperature fluctuations, this additional layer of protection can significantly improve the longevity of the handle. Here’s why oxidation is crucial:

Corrosion Resistance

Aluminium is naturally corrosion-resistant, but the oxidation process thickens the oxide layer, providing additional protection. This makes oxidation handles ideal for outdoor aluminium doors and windows, as they can withstand rain, humidity, and salty air, which would otherwise cause unprotected aluminium to corrode.Scratch and Wear Resistance

The oxide layer created during oxidation also makes aluminium handles more resistant to scratches and other surface damage. This is particularly important for high-traffic areas where the aluminium handles will be used frequently.Aesthetic Versatility

Oxidation handles can be made in a variety of colors, from classic metallic finishes to custom tones like bronze, black, and even gold. This makes it easier to match the handles with the colour of the aluminium doors or windows, enhancing the overall visual appeal. Whether you're aiming for a clean, minimalist design or a bold, contrasting look, oxidation handles offer versatile finishing options.

CNC Technology: Precision and Customization for Aluminium Handles

To ensure high-quality performance and appearance, many oxidation handles for aluminium doors and windows are crafted using CNC (Computer Numerical Control) technology. This advanced machining process allows for intricate, precise designs that meet specific industry standards.

What is CNC Technology?

CNC machining is a manufacturing process where a computer controls the movement of tools to precisely cut, drill, or shape a material. This is particularly useful for creating custom-designed aluminium handles for aluminium doors and windows. By using CNC technology, manufacturers can produce handles with exceptional accuracy, ensuring a perfect fit and flawless finish.

Advantages of CNC for Aluminium Handles

Precision: CNC technology ensures that every handle is made to exact specifications, guaranteeing consistency across large production runs.

Customization: CNC allows for the creation of unique, detailed designs that suit specific architectural needs, such as custom-sized handles or intricate patterns.

Efficiency: CNC machining speeds up the production process without compromising quality, making it ideal for bulk manufacturing of aluminium handles.

Applications of Aluminium Oxidation Handles in Doors and Windows

The combination of aluminium handles, oxidation, and CNC technology makes them perfect for various applications in aluminium doors and windows. Here are some common uses:

Sliding Doors and Windows

For sliding doors and windows, aluminium handles that are oxidized provide both smooth operation and durability. The oxidation process enhances the handle’s resistance to wear, especially in areas with high humidity or salty air. Oxidation handles are particularly well-suited for coastal properties, where salt spray can accelerate corrosion in untreated metals.Bi-Fold and French Doors

Bi-fold doors and French doors often require more robust handles. Oxidation handles offer the right balance of strength and style, ensuring that the handles can endure frequent use while complementing the sophisticated design of the door system. The enhanced durability of oxidation handles makes them a popular choice for high-end residential projects.Commercial and High-Traffic Applications

In commercial spaces like offices, retail stores, and hotels, oxidation handles are a perfect choice for aluminium doors and windows due to their resistance to corrosion and wear. The robust design ensures the handles perform well even in high-traffic environments. According to industry reports, oxidation handles are up to 30% more durable than standard handles in commercial settings, making them a cost-effective long-term solution.Outdoor and Industrial Applications

Oxidation handles are also widely used in outdoor and industrial settings, where exposure to harsh weather conditions and heavy use is common. Their enhanced corrosion resistance and durability make them ideal for applications such as warehouse doors, factory entrances, and outdoor gates.

Conclusion

When it comes to aluminium doors and windows, the importance of high-quality aluminium handles cannot be overstated. The integration of oxidation through the anodizing process significantly enhances the durability, corrosion resistance, and aesthetic appeal of these handles. With the added precision and customization capabilities of CNC technology, oxidation handles provide a superior solution for both residential and commercial door and window systems.

Whether you're working on a modern home renovation or outfitting a commercial building with aluminium doors, choosing the right oxidation handles ensures both functionality and style. The strength, security, and long-lasting performance provided by these handles make them an essential component of aluminium door and window systems.

WSMT supply premium quality aluminium accessories for windows and doors.

Welcome to contact us: whatsapp/Wechat/Zalo+86 150 156 88141

Email:catherine@weisidunwj.com